NANOINDENTATION OF TENDON

LAST UPDATED: 11/19/2020 by Amir Ostadi Moghaddam

I. Lab Logistics and Location

II. Motivation for the lab

III. Background

IV. Relevant Literature

V. Pre-lab Assignment

VI. Methods

VII. Analysis of Results and Discussion of Findings

VIII. Directions for the Teaching Assistant

I. Lab Logistics and Location

The third lab requires three meetings. The first meeting will be in the lecture room for the lab lecture. The TA will present an introductory lecture on the nanoindentation technique and contact mechanics. The contact mechanics theory is extremely important for understanding why the nanoindentation technique is so powerful compared to traditional hardness testing.

For the second meeting, students will meet during their scheduled time (detailed schedule on Piazza) for 50 minutes. We will meet in the EWS lab (MEL 1009) for the Nanoindentation simulation demo.

For the third meeting, students will attend one 60-minute slot (some times will be outside the usual lab times). Students will join the TA at the Materials Research Laboratory, located on Goodwin Avenue across from MEB, to first-hand engage with the nanoindentation system and observe indentations being performed on previously prepared samples.

Lab Write Up Policy

This lab may be written individually or in pairs. Lab reports will adhere to the normal 2-page extended abstract style report, see Lab Resources for more information. Your references can be listed on an additional page.

II. Motivation for the Lab

Indentation-based testing is a superior approach for local mapping of mechanical properties of inhomogeneous biological materials, such as cortical bone, cartilage, and tendon. Furthermore, this technique enables material property measurements at nano-level to micro-level length scales, which is relevant for building constitutive models for hierarchical tissues. With nanoindentation, local differences in mechanical properties not only between but also within microstructural components can be determined.

See Lab 2 for motivation for studying tendon.

While tensile and compression tests for measuring mechanical properties are more mainstream, these testing approaches lack clinical utility and only enable measurements of bulk mechanical properties. Compared to tensile and compression testing, an indentation-based approach for mechanical characterization of biological tissue is arguably more clinically applicable.

III. Background

Indentation Testing

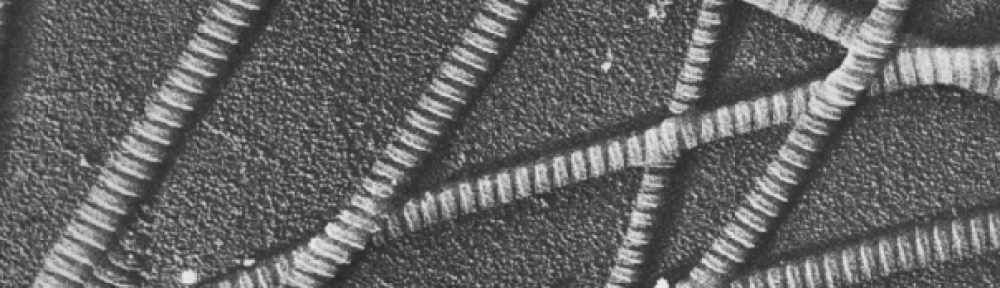

Mechanical testing will be performed on the Optics 11 Piuma Nanoindener for tendon at the Materials Research Laboratory. During the loading portion of indentation testing, the indenter tip is pushed into the sample to a pre-defined depth, and the force exerted by the sample on the tip is continuously recorded. During the unloading portion of the test, the tip is withdrawn from the sample. Force and displacement are continuously measured. For each indent in the sample, a load-displacement graph is generated. Elastic properties are extracted from the load-displacement data using elastic contact theory, which provides an empirical relationship between force, displacement, and elastic properties of a material. Previously, elastic contact theory has been used to extract elastic properties from indentation data for a wide variety of biological tissue, including arterial tissue, cartilage, sclera, and dentin.

IV. Relevant Literature

Recommended Reading

- W.C Oliver, G.M. Pharr “An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments.,” Journal of Materials Research 7(06), 1564-1583 (1992)

V. Pre-lab Assignment

The pre-lab assignment is due at the third meeting. Submit the pre-lab assignment to Compass by 11:59 PM of the Friday of the testing session. Components of the pre-lab assignment may be done individually or with a partner.

VI. Methods

Sample Preparation: Tendon

Porcine extensor digitorum lateralis tendon tissue was isolated in a similar fashion to Lab 2. The control tendon was stored in PBS and the collagenase-digested tendon was stored in 50 U/ml collagenase for 24 hours (See Lab 1 and Lab 2 for more details). The specimen were then placed in cryomolds and filled with an optical cutting temperature (OCT) compound and frozen until before slicing. Using a Leica CM3050 S Cryostat, several sections were cut to prepare the surface for nanoindentation.

Load Function for Nanoindentation

Tendon specimen are loaded into the Optics 11 Piuma Indenter, a cantilever indenter with stiffness 0.46 N/m, with a spherical probe attached (radius 53.5 micron).

To ensure that residual permanent deformation zones do not overlap, indents will be spaced 3-5 times the width of the residual indent. In other words, our indents will be sufficiently spaced from one another such that any given indent is not influenced by neighboring indents.

Mechanical testing of materials requires specification of a load function. We choose this function and input the function into the system. The function includes the loading and unloading rates, peak load, and hold segments.

We will use the position-controlled indentation. We use a trapezoidal position function as follows: load to 9 microns at a rate of 2 micron/s, hold at 9 microns for 1 second and unload to the neutral position at a rate of 2 micron/s.

VII. Analysis of Results and Discussion of Findings

Data Set

Optics 11 software will be used to automatically calculate the effective modulus for you using the same principles in class. Additionally, a select few raw data sets will be provided as samples so that you can see and plot the raw data. Details of calculating Young’s Modulus are provided in the lab lecture.

Lab Report Requirements

This report must be submitted in the Extended Abstract Style. You can submit this report individually, or in pairs. You will examine whether there are mechanical property differences in control and collagenase degraded tendon.

See Piazza for more details about report requirements.

VIII. DIRECTIONS FOR THE TEACHING ASSISTANT

The information below is intended primarily for the lab teaching assistant.

Biosafety

To ensure safe handling and disposal of animal tissue, it is recommended that the TA successfully complete theUnderstanding Biosafety training module from the Division of Animal Research at the University of Illinois at Urbana-Champaign.

Sample Disposal

Samples post-testing and all other biological waste that is generated should be discarded in accordance with the policies detailed by the Division of Research Safety (DRS) in the Treatment and Disposal of Biological Materials. To schedule pickup of pathological waste for incineration, the TA should go to http://www.drs.illinois.edu/biowaste. The TA should ensure that a completed DRS Incineration Tag is securely attached to the handle of each bag. Refrigerate or freeze waste between disposal and pickup.

Requisite TA Training

- In order to instruct students about the sample preparation undertaken for nanoindentation, the TA should receive training and gain sufficient experience. The appropriate contact for this sample preparation training is Professor I. Jasiuk. A graduate student from Professor Jasiuk’s lab may either elect to graciously conduct the sample preparation demo portion of this lab in their lab space (most preferred) or may provide training to you and allow you to lead the demo.

- The TA should receive training on the Hysitron TriboIndenter instrument. The training is quite extensive, so it should be scheduled well in advance of this lab. A second possibility is to request the MRL staff member in charge of the Hysitron TriboIndenter instrument to lead the nanoindentation sessions. This will allow the TA to avoid training on the instrument.

- The TA should become comfortable with the concepts important to nanoindentation by reviewing appropriate literature, as well as by leveraging the expertise provided by personnel at the Materials Research Laboratory.

- The TA should ensure that the “Bill of Materials” is fulfilled prior to beginning this lab.

Bill of Materials

Introductory Nanoindentation Lecture

Source: The TA

The TA presents an introductory lecture on nanoindentation and contact mechanics. It is important that the TA prepare for this lecture by reviewing literature, as well as consulting other resources.

Sample Preparation Demo

Source: TA or Jasiuk Group

Either the TA or a graduate student from Professor Jasiuk’s group will lead the sample preparation demo for students where polishing and grinding of cortical bone is demonstrated. It is important that the TA contact the Jasiuk group in advance of the beginning of the semester in order to schedule either the session with one of Professor Jasiuk’s students, or schedule the necessary training. The TA should aim to make initial contacts as early as possible and before the start of the semester if possible.

Porcine Femur Bones

Source: Meat Sciences Lab at the University of Illinois at Urbana-Champaign or Jasiuk Group

To provide the Meat Sciences Lab sufficient lead time, it is advised that the TA contact Chuck Stites [cstites AT illinois DOT edu] at least 4 weeks in advance of the lab start date. Once again, the TA should aim to make initial contacts as early as possible and before the start of the semester if possible. For a class of about 25 students, 2 porcine femur bones are minimally recommended (one for practice and one for use with the students).

Nanoindentation Sessions

Source: TA or MRL Staff member

Either the TA or a MRL staff member will lead the indentation sessions for students where the technique is demonstrated. It is important that the TA contact the MRL Staff member in advance of the beginning of the semester in order to schedule either schedule the indentation sessions with him or her leading the sessions, or schedule the necessary training.

Phosphate Buffered Saline Solution 1X

Source: Life Sciences Storeroom at the University of Illinois at Urbana-Champaign

Berkovich Probe

Source: Materials Research Laboratory

-20C Freezer

Source: Mechanical Engineering Building, Room 111/113

Lab Utensils and Materials

Source: Mechanical Engineering Building, Room 111/113 or Life Sciences Storeroom at the University of Illinois at Urbana-Champaign

a. Biohazard Trash Bags and DRS Incineration Tags

b. Dissecting Tools (scalpels, etc.)

c. Surface Disinfectant (70% Isopropyl Alcohol)

d. Methanol for cleaning Berkovich probe (if necessary)

If the sample preparation demo is lead by one of Professor Jasiuk’s graduate students, the bill of materials for this lab is not as extensive as her lab “donates” the materials and provides the equipment needed to prepare the samples successfully for nanoindentation:

a. Band saw

b. Precision diamond saw (Buehler Isomet 1000, Bueheler)

c. Grinder/Polisher

d. Silicon carbide abrasive papers (P1200, P2400, P4000)

e. 3 micron, 1 micron, 0.25 micron polishing clothes

f. 0.05μm alumina suspension micro-cloth.

g. Crystal Bond thermal glue

h. Customized glass petri dish (the wall height of the petri dish is important and has to be compatible with the nanoindenter)

However, if the sample preparation demo has to be conducted in the Wagoner Johnson lab, it is important that the TA ensure that the materials and the equipment that are needed to prepare the sample are available.